Australian scientist bags Ig Nobel prize with device creating world’s ‘most important medicine’ on the spot

An inventor from the Flinders University in South Australia has recently won an Ig Nobel prize with the development of a new device capable to create one of the world’s most in-demand anaesthetics on the spot. Developers say the device could aid faster innovation the global pharmaceuticals industry as well as food and biodiesel production.

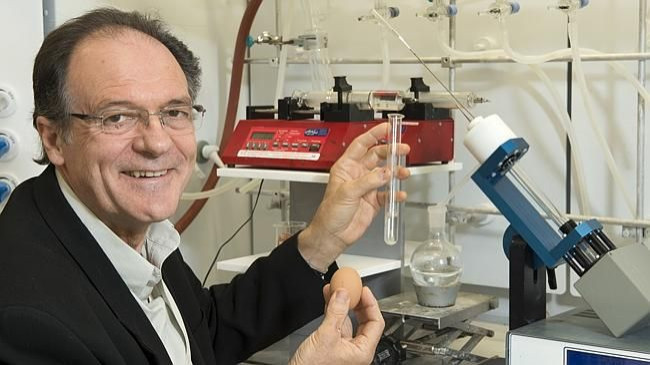

The inventor, Professor Colin Raston from the Flinders University in Adelaide, has successfully produced Lidocaine, one of the World Health Organisation’s “most important medicines for a basic healthcare system,” through his Vortex Fluidic Device or VFD. Raston and his team said the device could have huge implications on the traditional mass production methods by creating medicines in less than an hour.

Producing the anaesthetic Lidocaine in high speed is important in areas such as war zones and developing countries. The researchers said with the VFD, producing Lidocaine will be “so easy,” which would indicate a significant shift in pharmaceutical manufacture on creating medicines on the spot.

“The VFD uniquely controls how drug molecules can be made, and this is under continuous flow, such that research in making drug molecules can be readily translated into industry… just leave the VFD running to make as much as you need,” Raston said in a press release. The device would also allow industries to avoid conventional scale up problems and large reaction vessel, he added.

Raston pointed that the VFD will allow the pharmaceuticals industry to make the medicine even in the most remote locations by only using the basic instructions of manufacturing. The device has already been commercially available to research organisations around the world.

The development of the device has been funded by the National Health and Medical Research Council, the Australian Research Council and the South Australian government. Aside from creating Lidocaine, other medical and pharmaceutical research as well as other industries like food and biodiesel could use the VFD to create products on cleaner, greener and more cost effective production.

The VFD’s ability to “streamline the loading of drugs into nanopackages for better results and less waste” might help industries to set aside the traditional batch processing techniques, the researchers said. The assurance of VFD by creating more effective drugs could also help reduce manufacturing waste.

The production of just 1kg of various drugs can produce about half a tonne of waste, which are all being dumped in sewerage systems. In addition, Raston said that manufacturing wastes could lead to creating superbugs in the environment.

Contact the writer at feedback@ibtimes.com.au or tell us what you think below