Australia to employ robots to cope with huge warehouses

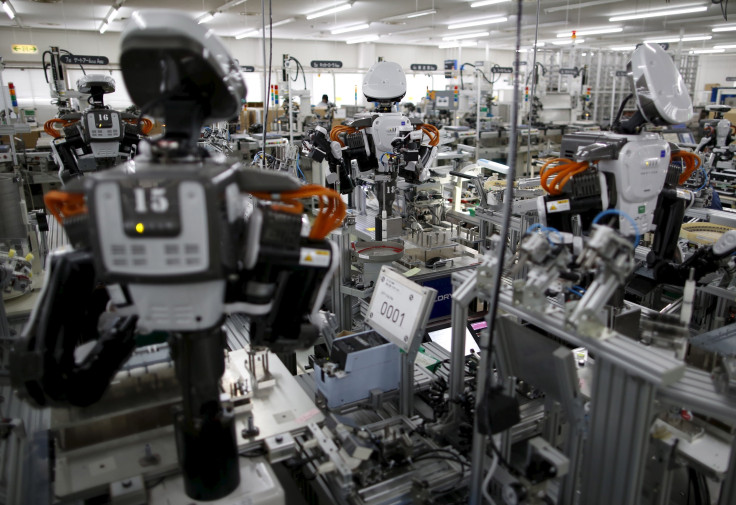

Experts say robots may soon be installed in warehouses in Australia, which continue to grow bigger to accommodate an increasing number of imports and e-tail goods.

According to a report by the SMH, robots will be necessary to cope with the sheer scale and location of these sheds which -- also because of their sizes -- will be situated away from current industrial zones in Sydney and Melbourne. In these situations, robots will be the best choice for 'employers' as they are essentially machines programmed to do a certain task, such as look for a bar code or deliver an item to a truck, and do not care where they live and work.

Nerida Conisbee, national director of research at Colliers International, said that the distribution centres have become more dynamic, with greater demand for natural light and enhanced floor space the more goods move and the higher clearances are needed.

"Occupiers are changing with third party logistics, or 3PL like companies such as Australia Post, Toll and DHL among others; experiencing huge growth and supermarket groups to become more refined in how they move goods through their distribution channels," said Conisbee.

Global resource giants BHP Billiton as well as Fortescue Metals are also adapting similar technology at their mines, said a Newsjs.com report.

Conisbee also feels that there is still a broad variation in how occupiers are efficiently using their space. “From highly automated picking systems requiring very little human interaction to boxes on the floor with paper based systems tracking stock levels, the evolution depends on the rate of change in the industry in which the occupier operates," she added.

According to the SMH report, Melbourne dominates Australia's ports with 36.7 per cent of twenty-foot equivalent units, or TEUs, the measure for containers, with Sydney at 32.3 per cent and Brisbane at 16 per cent.

"I would suggest that by 2018, it will not be unusual to see warehouses in Australia in excess of 200,000 square metre. Larger centres fitted out with sophisticated facilities, such as automated picking and sorting systems, are necessary in order for operators to benefit from economies of scale," said Malcom Tyson, managing director of industrial operations at Colliers International.

By 2018, there are chances that industrial warehouses across the main cities will be as much as 200,000 square metres in size.

Contact the writer at feedback@ibtimes.com.au, or let us know what you think below.