Wake Forest Institute develops 3D bioprinter that makes transplantable human ear

The Wake Forest Institute for Regenerative Medicine made known to the public its Integrated Tissue and Organ Printing System (ITOP). It is a 3D bioprinter that could generate tissue which could withstand transplantation.

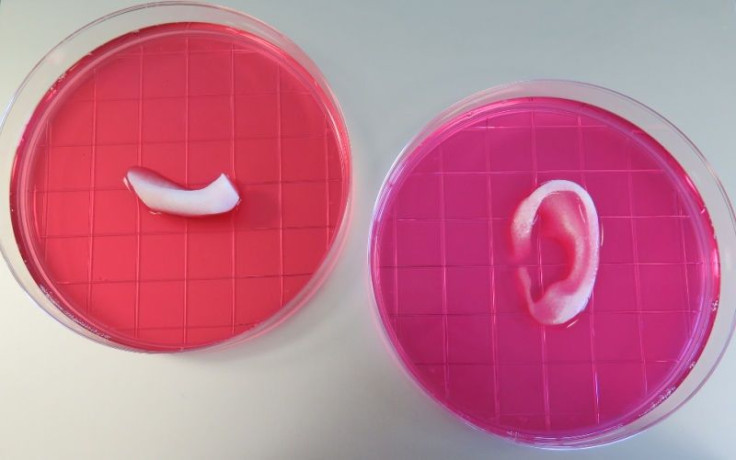

It took Wake’s research team, led by Anthony Atala, director and chair of the institute, almost a decade to develop the 3D printer. The team demonstrated the ITOP’s capability by printing an accurate human ear, made up of a jaw bone, muscle and cartilage structures, reports Gizmodo.

The ITOP uses special biomaterials which approximate living, functional tissues. However, since current bioprinters are not capable of making tissue of the right size or strength, most of the time its output is not good for surgical transplant. It likewise in incapable of printing blood vessels and other delicate body parts, without which cells cannot be provided with vital oxygen and nutrients.

Atala explains that because cells could not live without a blood vessel supply smaller than 200 microns, it was a limiting factor that challenge Wake to refine its bioprinter to address that issue. The institute did it by using biodegradable materials similar to plastic to form the tissue shape. To deliver the cells to the structure, the team use water-based gel because gels are not toxic to the cells. For oxygen and nutrients to be transported to cells within the structure, the team embedded microchannels into the design, recounts Atala.

The researchers tested the 3D-printed human-sized ears by implanting it under mice skin. Within 60 days, the cartilage tissue and blood vessels were formed, while the ears kept its shape. Next step was to print muscle tissues that were also implanted in the lab animal. The tissues likewise maintained its structural integrity.

The team is still refining ITOP, which, once approved as safe in humans, could be used to replace body parts that are missing, damaged or diseased. The body parts are designed in a computer, which means it could be tailored to meet the unique requirements of a patient. The next step then would be human trials.

Atala says, “Future developments of the integrated tissue-organ printer is being directed to the production of tissues for human applications, and to the building of more complex tissues and solid organs,” quotes 3ders.org. The study was published on Monday’s issue of Nature Biotechnology.