Queensland University of Technology builds space where researchers could develop technology for 3D printing of human organs

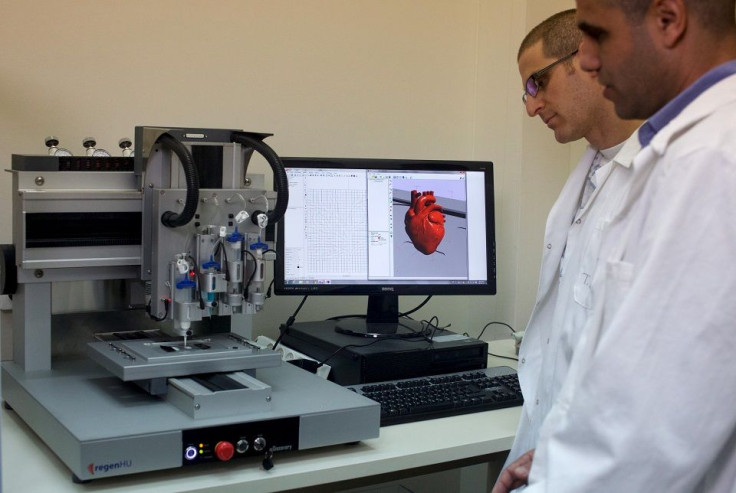

Australia’s Queensland University of Technology (QUT) is constructing a facility where researchers could develop technology that would model and print human body parts using 3D technology. The aim of QUT in creating a biofabrication space is to have in the future 3D printers in operating theatres that would be ready to print tissue when needed.

The facility targets to print cartilage, bone and other human tissues by using state-of-the-art tissue manufacturing technology, Engadget reports. The biofabrication institute would be in Brisbane’s Herston Health Precinct, the first time such a facility would be co-located with a high-level hospital, Queensland Health Minister Cameron Dick notes.

To be a collaboration among QUT, the Metro North Hospital and the Royal Brisbane and Women’s Hospital Health Service, the facility would open in 2017, PC&Tech Authority reports.

One of the challenges facing 3D printing is the lack of methods to ensure the implants made from 3D printing would be kept alive in the body and stop the implant from being rejected. Mia Woodruff, associate professor at QUT, says a lot of implants they have developed could implant into a patient and are not rejected as the tissue grows back.

The scaffold they made would reabsorb over time, allowing the tissue to grow more until the implant is gone. Instead of metallic implants, they are now developing high-spec composite materials that dissolve as the tissue heals, Woodruff explains.