Investing in graphite stocks should keep it and the tech industry afloat

With the constant development of technology, materials needed in creating the ever increasingly sophisticated equipment, machinery and gadgets are also getting more unique and complex. Minerals are required to make some items needed to power technology, such as lithium-ion batteries. These are found in smartphones, laptops and even electric cars as they are used to power up these devices, which have become necessities these days.

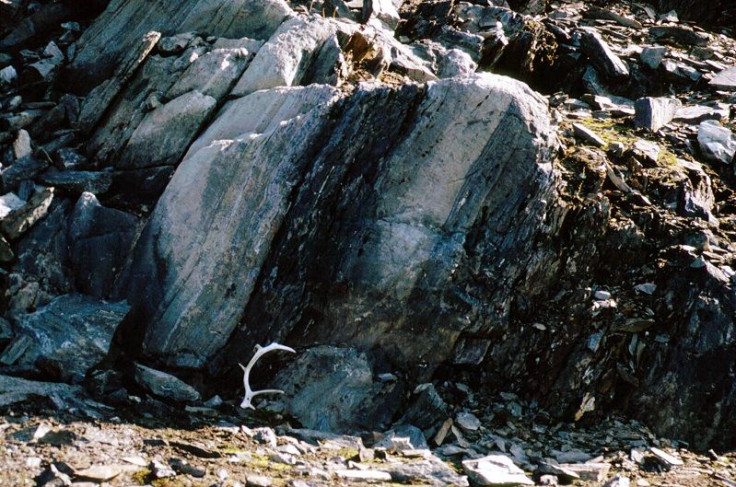

These batteries need some minerals to be made, and one of the largest battery component is the graphite anode. Graphite is made up of carbon, similar to diamond. However, these two minerals are different when it comes to molecular structure, resulting in contrasting traits between the two.

Additionally, graphite materialises upon carbon’s exposure to heat and pressure. To produce the mineral, it must be subjected to approximately 750 degrees Celsius and an estimated pressure of 75,000 pounds per square inch.

The struggle of an in-demand industry

Graphite is a common mineral. Despite the fact, however, it can also be prone to scarcity because of its significance in the tech industry. It is even considered a vital mineral for the future of the economy of both Europe and the United States, Investment U noted in 2012. Back in 2000, at around 600,000 tons of natural graphite were used. Eleven years later, the consumption has risen to 1.1 million tons, with an annual five percent increase in demand starting in 2000.

And now, it has been reported that the tech-grade graphite supply is running low. The news has certainly brought uncertainty to the future of electric cars. The report stated that the United States is the country that consumes most of the graphite. What is even more disturbing is that it does not have companies that focus on manufacturing graphite.

In a world where technology evolves rapidly, it looks like the graphite demand will keep on rising, with an increase of 200 percent anticipated to occur in almost three years and a 300 percent upsurge eyed in 2025. If the United States wants to keep the electric car industry sailing, it might want to address the graphite shortage situation. Perhaps one way to deal with this concern is to invest more in graphite stocks. Investing in the stocks of graphite manufacturers can help them produce more of this mineral. In effect, it would help them meet the ever-growing demand for batteries.

In recent news, China is taking the initiative to raise the global processing capacity of graphite by 2020 to satiate the demand for lithium-ion batteries. Chinese companies like Shanshan Technology, LuiMao Graphite and BTR New Energy are constructing mega-factories capable of processing a total of 260,000 metric tons yearly. China, however, has been known to use non-environmental mining processes.

Japan is also stepping up its game in the graphite industry as Hitachi Chemical works on setting up a manufacturing establishment. The facility will have a processing output of 100,000 metric tons each year.

Aside from Japan and China, Canada is making contributions to the plate. The country is known to be one of the biggest producers of graphite, with total production amounting to 21,000 MT. China leads the pack with 780,000 MT, while India and Brazil follow with 170,000 MT and 80,000 MT, respectively.

Many graphite companies are located in Canada. One company is levelling up its efforts in chipping in the global production of graphite.

Based in Bedford, Canada, Elcora Advanced Materials (ERA.V) integrates graphite mining with the tasks of processing, refining and producing graphite materials with clean technology. The company’s graphite output is dedicated to the production of more lithium-ion batteries. Its graphite does not have chemical processing and is also not tainted with silica.

The company has a processing plant in Sri Lanka. It also operates the Sakura graphite mine, which is located in the same country. The mine’s current production capacity each year is at 1,800 tons. However, it has plans of taking it up to 5,000 tons in the first quarter of 2018 and 10,000 tons by 2021.

Elcora also produces graphene, another form of carbon. Its graphene output came from natural graphite. In fact, the National University of Singapore’s Centre for Advanced 2D Materials has successfully tested Elcora’s graphene as one of the best in the world. Elcora is currently developing graphene-based coating applications such as anti-fouling marine paint.

Meanwhile, there’s Ceylon Graphite (CVE:CYL), a graphite company located in Vancouver, Canada. Recently, it made a deal to acquire Sri Lanka-based mining company JADS Enterprises. JADS is equipped with five graphite exploration Grid units or GRIDs. Ceylon will also acquire these units.

When the acquisition deal is finally completed, Ceylon aims to perform a limited drilling program on the Panliyadda site, which is situated at the Malsiripura property. This program will determine the amount and quality of the graphite mineralisation and will also help in conceptualising a mine plan. To help more companies meet rising demands due to rapid evolution and production of technology, investments in graphite stocks would definitely be vital in their efforts, keeping afloat not only the graphite industry but also the tech industry.