Elcora’s proprietary Li-Ion processing plant exceeds Clean Tech manufacturing standards

Few people would question that air pollution and climate change are problems that need to be tackled. While some countries are reviewing ways to lower carbon dioxide emissions, others are taking action by enacting new legislation promoting the development and expansion of electric vehicle (EV) technology. The United Kingdom has been a first-mover in that direction by modifying the design of its iconic black cabs in an attempt to combat climate change.

In the US, an ever-increasing amount of states are aggressively adopting legislation favouring the expansion of electric vehicle fleets. Manufacturing companies in the EV space, like Tesla, which recently announced their E-Truck Semi, are doubling down on their efforts to ramp up production. These concurrent trends have caused the demand for raw materials needed in the EV manufacturing process to explode. But how far ahead do consumers get if the manufacturing standards remain sloppy?

Rising demand

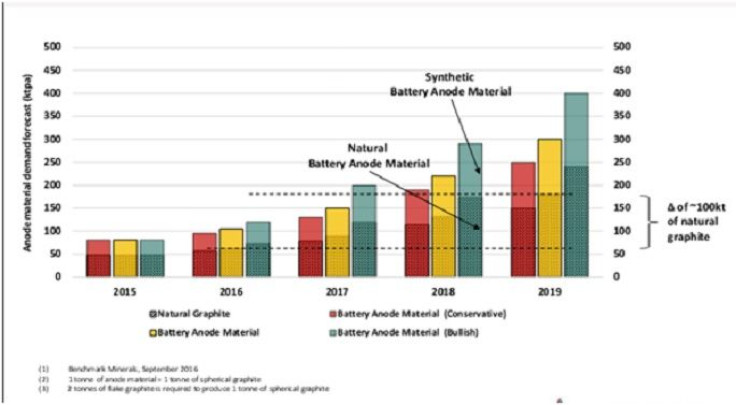

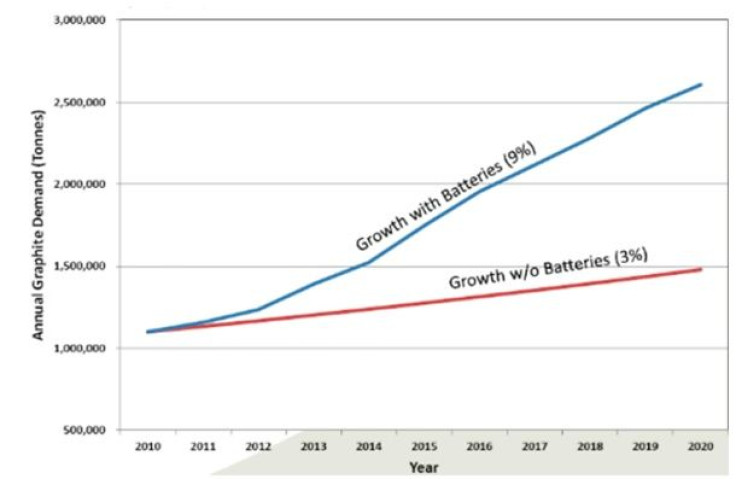

Last year, Benchmark Mineral Intelligence, a price data collection and assessment company based in London, reported that graphite demand will see a large increase in the coming four years as more Li-ion battery cells are manufactured. The anode market alone is expected to witness 200 percent growth in demand, jumping from 80,000 TPA to 250,000 TPA by 2020. The anode market may even reach 400,000 TPA assuming no restrictions in the supply chain.

Benchmark also stated in its 2016 data that spherical graphite will require over 360,000 tons of flake graphite as a feedstock source, which is double the size of the entire flake concentrate market in 2015.

The growing demand for electric vehicles has pushed manufacturers to build giga-factories across the globe and primarily across parts of Asia and Europe. This aggressive demand curve has put a serious strain on the graphite supply chain, at a risk of creating an actual supply shortage.

Elcora rises to the occasion

One company, in particular, has been working on developing a process that may provide an immediate solution to the requirements of battery manufacturers. The same company seems prepared and determined to satisfy the growing industry demand for graphite.

Elcora Advanced Materials Corp. (TSXV:ERA), was founded in 2011 as a vertically integrated graphite and graphene company. The company mines, processes, refines graphite and targets high-end graphite markets including Li-ion batteries and graphene R&D.

The graphite Elcora produces is ideal for the manufacturing of lithium-ion battery anodes. The graphite anode powder is of exceptional quality at competitive pricing.

As a vertically integrated company, Elcora has been streamlining its operations and manufacturing processes. The company’s state of the art processing plant eliminates the need for spheronisation, purification, and the development of coatings. As a result, independent testing shows that Elcora Anode Material meets or exceeds vehicle battery industry standards. Elcora is boosting its production output in an effort to satisfy the demand of Li-ion battery manufacturers. The core strategy is aimed at lowering emissions of carbon dioxide while lessening both the energy footprint and associated expenses.