Food inspection system made of nickel-alloy reduces food contaminants

Researchers and scientists from Japan’s Department of Environmental and Life Sciences at Toyohashi have developed a device made of nickel-alloy that detects metallic contaminants in food.

Metals are considered to be the most common food contaminant, constantly presenting safety and health hazards to consumers all over the world. Metal chips from processing equipment and heavy metals such as mercury, lead and cadmium are often found in processed food. If taken in significant doses, mercury can cause brain damage, deafness and blindness.

Although high fructose corn syrup have high levels of mercury, a third of 55 popular food and beverage brands such as Kellogs, Capri-Sun, and Ben & Jerry’s still have it as their first or second main ingredient.

The food inspection system developed in Toyohashi is based on superconducting quantum interference devices (SQUIDs), and has been described in a paper published in the IEEE Transactions on Applied Superconductivity.

This system is a more effective way of examining food compared with the usual X-ray radiation method. The latter cannot detect contaminants smaller than 1mm and cannot be used for foods that have lactic acid bacteria such as dairy products.

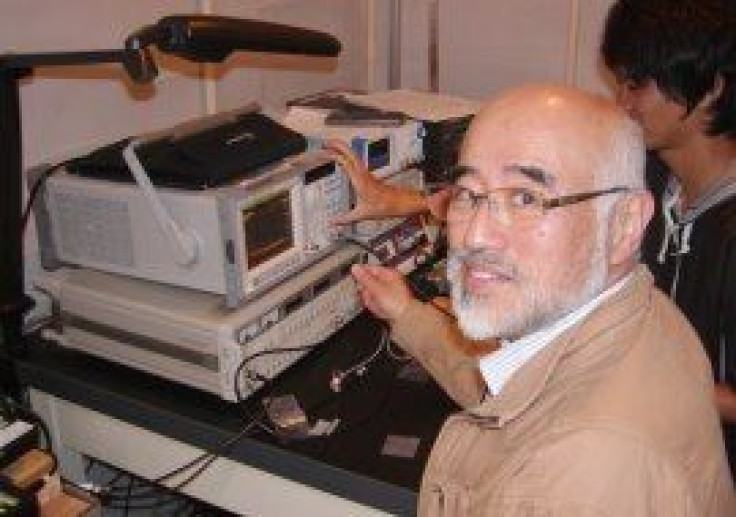

Headed by Professor Saburo Tanaka, the system uses a detection method based on recording the magnetic field of a contaminant. A powerful magnetic field is initially applied to the food to show the metal fragments within.

“We have developed an inspection system that permits contaminant detection in a food package with a height of 100mm with three high temperature superconductivity radio frequency SQUIDs. To accurately detect even smaller metallic fragments, digital filters have also been used to improve the signal-to-noise ratio,” explained Tanaka in a report by Asian Scientist.

Tanaka explained that the food sensor is placed inside a square metallic box to reduce the impact of noise. The box is made of 2-mm iron-nickel alloy plates, to which magnetic fields have strong affinity with. As a result, the magnetic fields around the sensor are concentrated on the walls of the box. Food that passes the metallic box are then tested for contaminants.

If Tanaka’s food inspection system gets more exposure around the word, more nickel will be needed. Russia’s Amur Minerals Corporation ( London AIM: AMC ) is currently building its own smelter to process high-grade nickel and copper ore in its Kun-Manie deposit. Once the company begins production, more nickel could be used for scientific experiments such as the one done in Toyohashi.

Contact the writer at feedback@ibtimes.com.au or tell us what you think below