Australian university gains global attention for discovering material that absorbs oil spills

Two years after discovering a lightweight and reusable material that can absorb soak up a wide range of oil spills, chemical solvents and dyes in water, an Australian university has caught the world’s attention.

The study, conducted by Deakin University, was published in Nature Communications in April 2013 and was selected as one of its main news story on its website.

“We have been bombarded by the international media seeking stories and interviews,” says Deakin’s Professor Ian Chen, who led the research team of Dr Wei Wei Lei, David Portehault, Dan Liu and Si Qin.

The effective removal of oils, organic solvents and dyes from water is of significant, global importance for environmental and water source protection, according to Lei, the Alfred Deakin Postdoctoral Fellow who played a key role in the project.

“In our paper we report on porous boron nitride nanosheets with very high specific surface areas that exhibit excellent sorption performances for a wide range of oils, solvents and dyes,” Lei says.

The nanostructured material absorbs up to 33 times its own weight in oils and organic solvents while repelling water, the team reports. Highly porous, the sheets have a high surface area, can float on water and are water-repellent, they add.

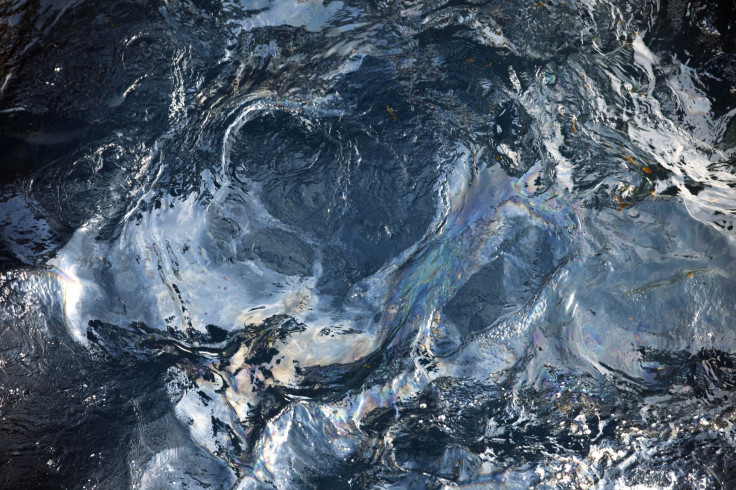

Once dropped on an oil-polluted water surface, the white sheets immediately absorb the brown oil and become dark brown, the researchers wrote in the study. The process only takes for merely two minutes, they report.

The sheets can be easily picked up from the water surface and cleaned by burning, heating or washing to be reused several times.

According to the team, it has been known since the early 1930’s that boron 10 has the ability to capture neutrons, the team notes. However, manufacturing pure boron nitride nanotubes in large quantities has been an issue.

Chen and his colleagues have developed a ball milling method that has overcome the problem of producing the boron nitride nanotubes in commercial qualities.

The team also reports that their discovery seems to have applications way beyond water purification.

Research teams led by Chen have been working on various boron nitride nanomaterials for more than a decade. “I have also been working with researchers at NASA about the possible applications of boron nitride nanotubes in space missions,” he says.

Several years ago, NASA researchers asked him to prepare boron nitride nanotube samples for tests on the space station. He says there will also be more earthly uses for the boron nanotubes, including the production of electrical power.

Contact the writer at feedback@ibtimes.com.au or tell us what you think below.